Construction

Cranes

Cranes

The construction industry has benefitted from cranes since the Grecians used a pulley system with stones ensemble dating back to 515 BC. Many could be used with a pulleys and wheels, making them one of the first large pieces of equipment to aid man’s work before power and gas were available.

| The Breakdown | |||||||||||||

Types of Cranes

Today’s cranes have become much more complicated beasts capable of increasing a schedule with an elegance that can’t be matched. There are many types of cranes, but for simplicity, we’ll stick to these four: Gantry, Truck or Wheeled, Tower and Crawler cranes.

Gantry Cranes

Normally found in warehouses, harbors and distribution centers. Typically you’ll see them with two legs and a crane on a track that moves back and forth picking up crates off ships and placing them on the docks.

Truck or Wheeled

These cranes are mobile, usually for lighter loads and not necessarily a critical aid in the construction of a building. These typically deliver a piece of equipment or a vehicle.

Tower and Crawler

These cranes are the most typical cranes to the building industry. Many general contractors own tower and crawler cranes for simplicity and economic ease. With over 20 subcontractors on a new building contract, it wouldn’t be feasible to have a different crane for each trade (especially on a high-rise) so the general contractor will either rent or use an owned crane and include that in the total contract value.

Though tower cranes can be mobile, the most typical application is a fixed base with deep piles or a spread footing. Tower cranes have a strict tolerance for plumbness, usually requiring the structure be built within 1 inch in 40 feet or a 1:500 ratio. This places a lot of importance on the foundation of the crane, where the flatness of the footing, and level anchor nuts determines how plumb the crane will be. There’s little room for error, as these anchors and footing are usually a 6-foot deep assembly.

Parts of a Crane

Some important components of a crane are as follows:

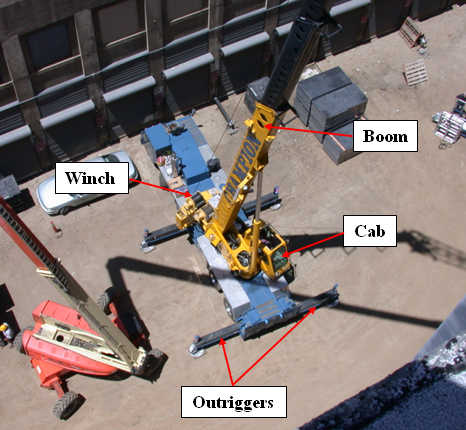

Fig 1: The components of a Crane

- Boom

- This is what extends the Jib of a crane, either hydraulic and telescoping pipe or a fixed length of latticed steel.

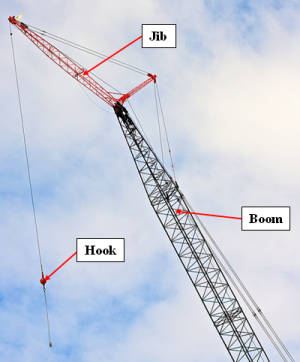

Fig 2: The components of a Crane (Photo: jeff_golden)

- Jib

- This is what carries the load at the end of a boom, or located horizontally on top of the tower crane.

- Outriggers

- These leg-like supports are located at the base of the crane and help prevent overturning.

- Cab

- This is usually where the operator sits. In a tower crane this can be near the top Jib, and in a crawler crane, this can be located at the base.

- Pulleys

- There are pulleys and cables in place that keep the crane boom and jib extended, as well as pulleys that hold the load. These cables will never do double duty, and are kept separate from one another.

- Hook

- This is typically the piece at the end of the pulley that holds the load. If it’s not a hook, it is a closed chain link similar to a carabiner thats a full closed loop with no option to open.

- Winch

- The mechanical motor that lets the crane line in and out.